Electro Casting Resins

Electrocasting resins are key to the further development of numerous industries such as automotive, energy, automation and white goods.

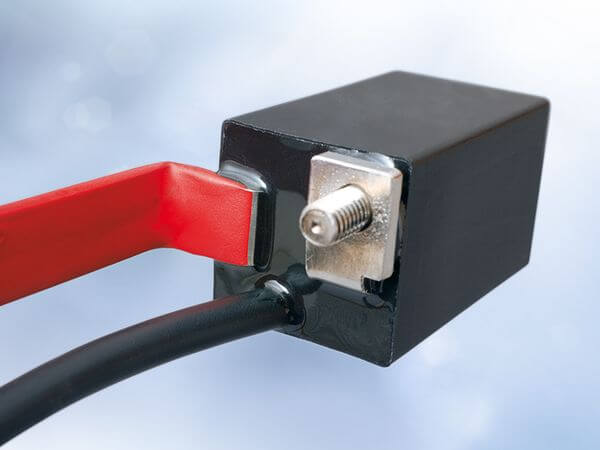

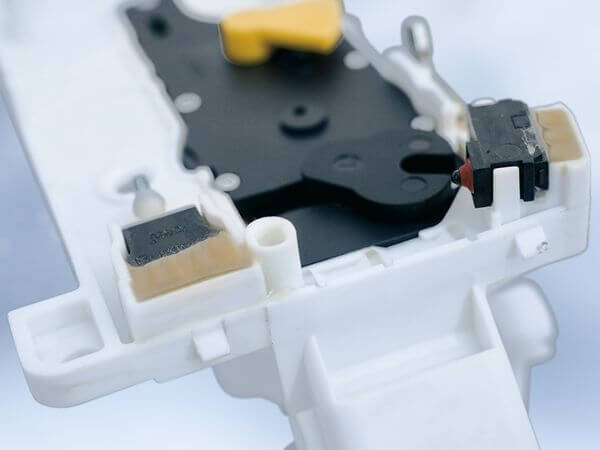

PTIL one- or two-component electro-casting resins increase the reliability and performance of your parts while ensuring their cost efficiency and longevity. They provide reliable and efficient protection to your parts (transformers, control units, inverters, motors, sensors, etc.) against chemicals, environmental effects such as heat, cold and humidity.

Customers using our polyurethane (RAKU® PUR), epoxy (RAKU® POX) and silicone (RAKU® SIL) based electro-casting resins include leading manufacturers in the automotive and electronics industry.

PTIL electro-casting resins have a wide range of mechanical, thermal and chemical properties. It provides low thermal stresses by removing the heat from your parts in the most efficient way.

Even with extreme temperature changes, our casting resins retain enough flexibility to relieve stress on your parts.

Our premium electro-casting resin products are complemented by the extensive application expertise of PTIL, one of the world's leading experts in mixing and dosing systems.

Material, machine and process; Benefit from PTIL's high-quality full service.

Our advantages

● High mechanical and thermal resistance ensures long-term functionality of your application

● More than 35 years of experience in developing and manufacturing innovative electro-casting resins

● High thermal conductivity

● Our products are RoHS and UL 94, RTI, OBJS2 etc. conforms to test standards / listings.

● Wide application areas thanks to innovative, customized product development

● Wide range of features optimized for your needs

● High resistance to temperature fluctuations

● Use by leading manufacturers in the automotive and electronics industry

Applications

Sensors

Switches

Sensors

Drivers

Engines

Relays

Relays

Door Closing / Locking Units

Electronic Components

White Goods

Charging Connector for Electric Vehicles

Power and Control Units

Transformers

Which Electro Casting Resin is Most Suitable for You