Engineering Casting Resins

At RAMPF, CASE stands for highly flexible elastomers, specialty casting and construction materials, and an all-encompassing portfolio of innovative reaction resins.

Usage areas of our RAKU® PUR (polyurethane), RAKU® POX (epoxy), RAKU® SIL (silicone) and RAKU® Melt (hot melt) products:

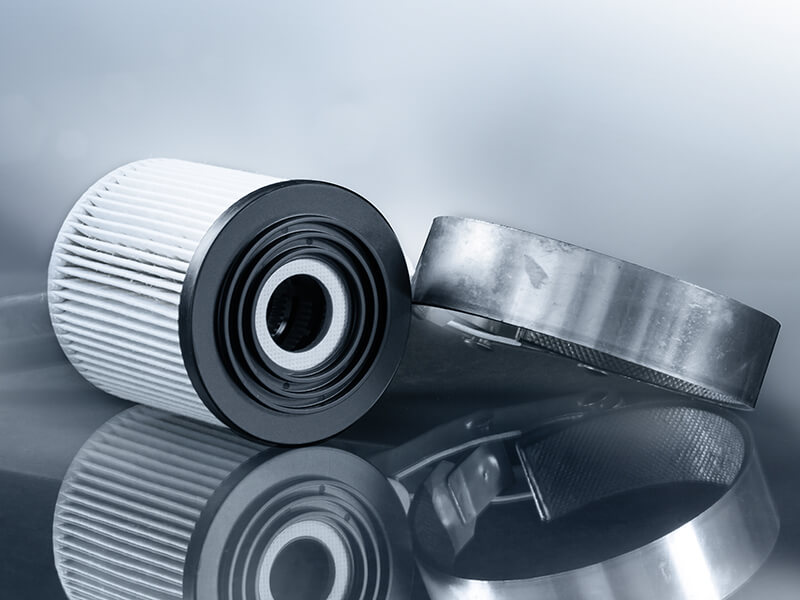

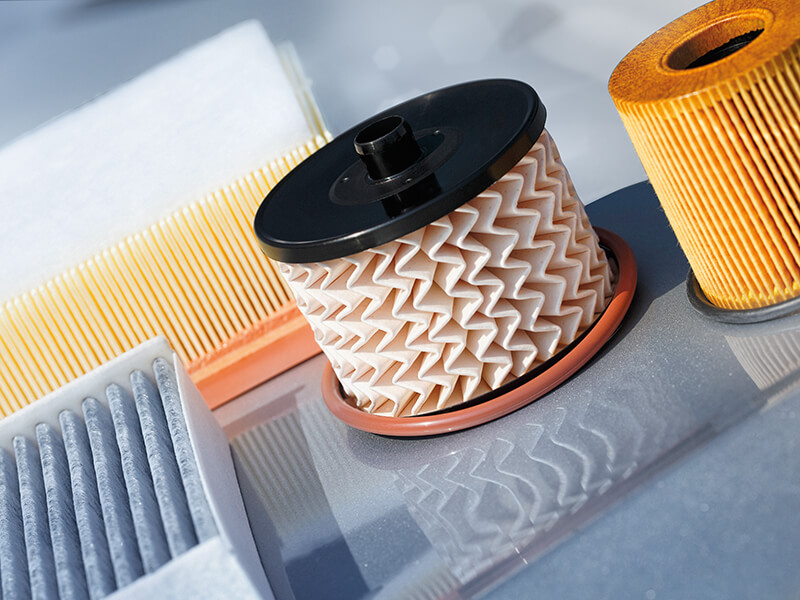

● Filters (cast, air seal, oil and hydraulic filters)

● Insulation panels (gelcoat layer and foam) for refrigerated vehicles

● Gluing window frames

● Corner casting applications for laboratories, hospitals and school tables and benches

● Elastomer molds for the cement industry

● Abrasives, sanders, mops

Applications

Hydraulic Filters

filters

School Tables Edge Casting Coating

Laboratory Furniture Edge Casting Coating

Train Tables Edge Casting Coating

Gasket and Adhesive System for Air Filters

Sanding and Polishing Industry

Artificial Stone Molds

The best combination for your needs

We work with you to develop the best solution for your applications.