Sealing Systems

Reliable and Efficient Protection

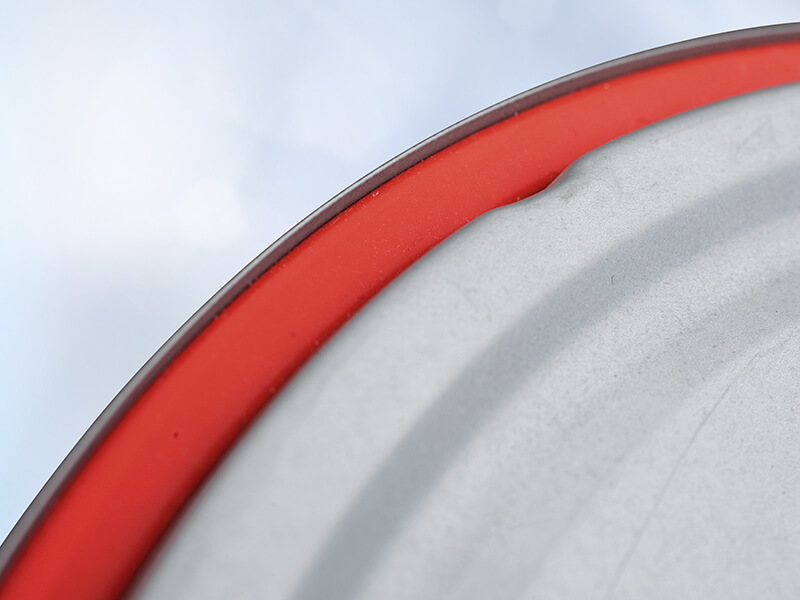

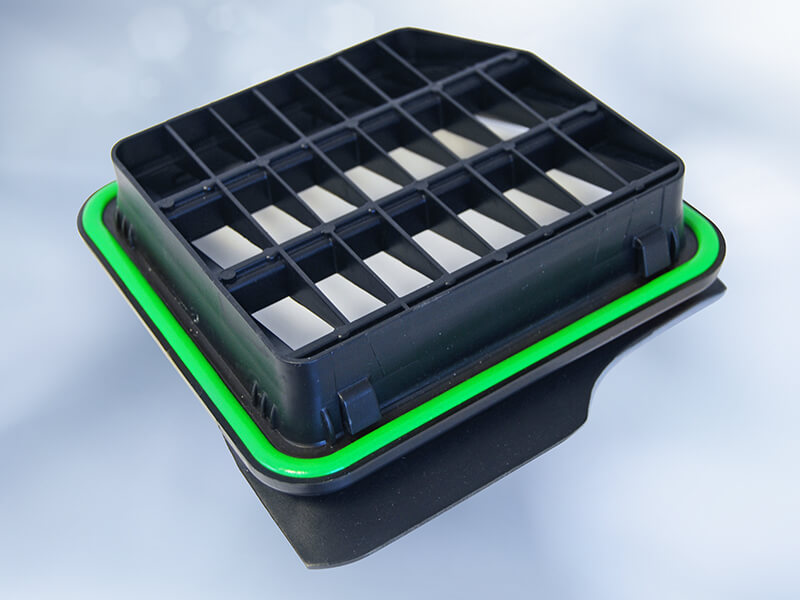

The main task of sealing systems is to effectively protect components against moisture, chemicals and various environmental influences.

RAMPF Polymer Solutions is a leading specialist in polyurethane and silicone based, liquid and thixotropic two component cast gaskets.

Polyurethane and silicone cast gaskets are processed using FIPFG (formed in place foam gasket) or FIPG (formed in place gasket) technology.

Compared to the ready-made gasket systems that are glued by hand, cast gaskets are directly applied to the desired surfaces with dosing units or cast gasket machines, providing fast adhesion and rapid mass production, minimizing process times and producing much more efficient results.

Our RAKU ® PUR and RAKU ® SIL systems provide the highest quality and ease of use with their highly efficient sealing.

By developing new products and optimizing existing ones, Rampf always meets the toughest demands in terms of gasket quality, sealing geometry, mechanical, thermal and chemical resistance.

According to customer requests, reaction rates, viscosity and color options can be adjusted with endless formulation options.

Our advantages

● Many years of experience in product development and process technology

● IATF 16949 and ISO 14001 certificates

● Providing highly efficient sealing by applying Polyurethane and Silicone Cast gaskets with automatic systems

● Being the preferred supplier for indoor and outdoor applications in automotive, white goods, lighting, electrical electronics and packaging industries for many years

● High efficiency sealing of Polyurethane and Silicone Cast gaskets with automatic applications

● Economic benefits thanks to accelerated and simplified production and assembly processes

● Sound and vibration absorbing feature

● Reliable and long-lasting sealing, the gasket adheres tightly to the applied surfaces and cannot be removed again

● Perfect compatibility with pour seal machines and dosing systems

Applications

Packaging Cover

Electronic Boxes

Automotive Trunk Ventilation

Household appliances

Automotive Lighting

Industrial Lighting

Speaker Boxes

Electronic Boards

Which Sealing Area Is Most Suitable For You